At Goodwill Engineering & Goodwill Pipeline Inspection LLC, we provide a comprehensive range of Heat Treatment services designed to enhance material performance, reduce residual stress, and ensure long-term structural integrity. Our capabilities include Pre-Heating, Post Weld Heat Treatment (PWHT), Hydrogen Release, Induction Heating, Furnace Heating, Line and Bolt Release Heating, as well as Composite and Refractory Dry-Outs. These services are essential in critical applications across industries such as oil & gas, petrochemical, power generation, and construction. Utilizing advanced heating technologies and precise temperature control systems, our qualified technicians ensure uniform heat distribution and compliance with industry standards like ASME, API, and AWS. Whether performed on-site or at our facility, each heat treatment process is meticulously monitored and documented to deliver consistent, safe, and reliable results that meet both operational and regulatory demands.

Pre-Heating

GEI provides Pre-Heating services to ensure materials are properly conditioned before welding or fabrication. This controlled heating process reduces the risk of thermal shock, cold cracking, and hardness in the heat-affected zone (HAZ). Using advanced heating methods such as resistance heaters, gas torches, and induction systems, our team ensures uniform temperature distribution in line with industry codes like ASME and AWS. Pre-heating enhances weld quality and prolongs the lifespan of critical components.

.jpg)

Post Weld Heat Treatment (PWHT)

GEI provides Post Weld Heat Treatment (PWHT) to relieve residual stresses and restore the mechanical properties of welded materials. We offer both localized and furnace-based PWHT services, tailored to meet the specifications of ASME, API, and other international standards. Our calibrated systems and certified technicians closely monitor temperature cycles to ensure controlled heating and cooling, delivering consistent and compliant results for pressure vessels, pipelines, and heavy structural welds.

Hydrogen Release Treatment

GEI provides Hydrogen Release Treatment—a critical service to prevent hydrogen-induced cracking, especially in high-strength steels. By heating welded components to a specific temperature shortly after welding, we remove diffusible hydrogen from the weld and heat-affected zones. This process helps maintain structural integrity, reduce failure risks, and meet stringent code requirements. Our expert team ensures each treatment is applied with precision and verified through controlled temperature monitoring.

Induction Heating

GEI provides Induction Heating services for rapid, efficient, and localized heating of metallic components. This method is ideal for pre-heating, PWHT, shrink fitting, and bolt loosening, offering precise control and uniform heat distribution. With portable induction units and experienced operators, GEI performs safe and reliable on-site heating, minimizing downtime and improving turnaround times during shutdowns, maintenance, and fabrication activities.

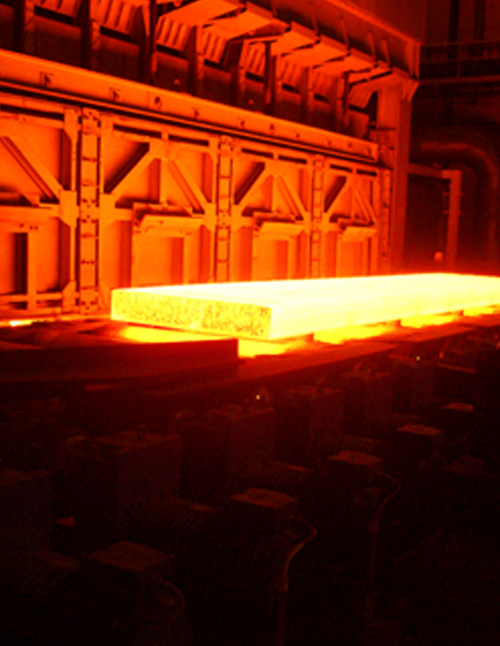

Furnace Heating

GEI provides Furnace Heating services for components that require uniform and high-temperature heat treatment. Our industrial furnaces are capable of stress relieving, annealing, normalizing, and PWHT under controlled conditions. This service is ideal for batch processing or large parts that demand consistent thermal treatment. GEI ensures each furnace cycle is executed with full traceability, documentation, and compliance with applicable standards.

Line and Bolt Release Heating

GEI provides Line and Bolt Release Heating to assist in the safe and efficient disassembly of flanged joints, pipelines, and mechanical fasteners. We use localized induction or resistance heating to expand metal components, allowing for non-destructive removal during maintenance or shutdown activities. This service reduces the risk of part damage, saves time, and enhances safety in high-pressure or high-temperature environments.

Composite and Refractory Dry-Outs

GEI provides Composite and Refractory Dry-Out services to ensure proper curing of new linings in furnaces, reformers, kilns, and reactors. Controlled heating is applied to gradually remove moisture from refractory materials, preventing steam spalling and structural failure. Our expert team follows OEM-recommended heat-up profiles using precise temperature control and real-time monitoring, delivering safe, effective, and code-compliant dry-out operations.

| S.no | Benefits of Post Weld Heat Treatment |

|---|---|

| 1 | Relaxes residual stresses |

| 2 | Relaxes thermal stresses |

| 3 | Tempers the metal |

| 4 | Removes diffusible Hydrogen |

| 5 | Metallurgical structure is improved |

| S.no | Service Offered |

|---|---|

| 1 | Independent / 3rd Party Inspection Agency |

| 2 | ASNT NDT Level III Consultancy Services |

| 3 | ASNT NDT Level II Training Services |

| 4 | Consultancy on welding, quality control/assurance & testing/inspection |

| 5 | Qualification of welders & welding procedures |

| 6 | API 653 / 510 / 570 Authorized Inspectors Supply |

| 7 | Quality Assurance & Quality Control Inspectors Supply |

Fast Turnaround

We provide our Heat Treatment services with a quick and efficient turnaround time to minimize your operational downtime.

Heat Treatment Services

We provide heat treatment services like Pre-Heating, PWHT, Hydrogen Release, Induction and Furnace Heating to improve material strength, reduce stress, and support safe welding and fabrication.

Experienced Technicians

Our team includes highly skilled and certified professionals with extensive experience in diverse industries.